The Primary Differences Between Single and Double Acting Hydraulic Cylinders

Hydraulic cylinders, with a body composed of a hose, pump, and cylinder, are used in a wide variety of equipment, vehicles, and tools where heavy lifting is necessary. And, in this post, we are going to discuss the primary differences between two types – single and double acting hydraulic cylinders.

Single Acting Hydraulic Cylinders

Single acting hydraulic cylinders are the best choice for applications where gravity, weight, or another types of assist force is available to move the cylinder in a single direction as the hydraulic fluid only applies pressure to one side of the piston. As force is applied the cylinder shaft extends and oil is pumped. In general, single acting hydraulic cylinders are simpler and less costly than their double acting counterparts as well as being easier to maintain as there is only force being applied in one direction.

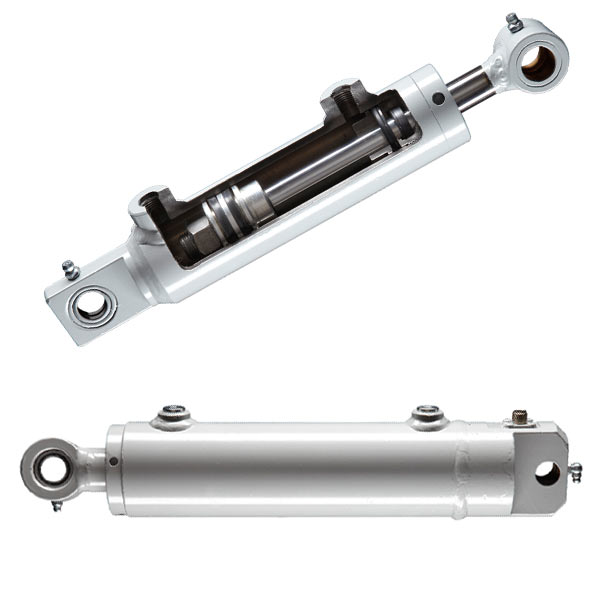

Double Acting Hydraulic Cylinders

As you may have guessed, unlike single acting hydraulic cylinders, double acting hydraulic cylinders have hydraulic fluid on both the base and the rod sides of the piston with force being delivered in both directions allowing both retraction and extension without the need of an external force. More common than single acting hydraulic cylinders, double acting hydraulic cylinders work at any angle and nearly every application where hydraulic power is needed.

At Best Metal Products, we have over sixty years in the custom hydraulic cylinder industry where we have earned a reputation as a leader in the design, prototyping, and manufacturing of hydraulic cylinders in the industrial and mobile hydraulic cylinder markets. So, whether you’re in need of a single acting or double acting hydraulic cylinder for your application, you can trust the experts and Best Metal Products. If you have any questions or would like to partner with us, do not hesitate to contact us today!